2025-12-08

Biodegradable Magnesium & Magnesium Alloys: Driving the Next Generation of Implantable Medical Materials

In the field of implantable medical devices, the goal is not only to ensure safety and durability, but also to develop materials that can “complete their mission and retreat gracefully.” Ideally, implants should support tissue repair and then naturally degrade, eliminating the need for secondary removal surgery.

Driven by this clinical demand, biodegradable biomaterials have become a major research focus in medical engineering. Among these emerging materials, biodegradable magnesium (Mg) and magnesium alloys stand out due to their biological functionality, degradability, and excellent biomechanical compatibility.

1. Core Properties of Magnesium-Based Materials: Lightweight, Safe, Biocompatible

Magnesium is one of the lightest structural metals, offering a combination of strength, ductility, and creep resistance. Unlike conventional titanium alloys or stainless steel, magnesium’s density and elastic modulus are closer to human cortical bone.

- Density: 1.74–1.84 g/cm³

(close to natural bone: 1.87–1.97 g/cm³) - Elastic modulus: 41–45 GPa

(closer to cortical bone: 12–23.3 GPa)

This closer match helps reduce stress shielding—a common issue with overly stiff implants—thereby supporting healthier bone remodeling.

Common magnesium alloy systems include:

- AZ series (Mg–Al–Zn): Widely used, balanced performance

- WE series (Mg–Rare Earth–Zr): High strength and thermal stability

- ZK series (Mg–Zn–Zr): High strength, often used in aerospace and automotive components

2. Magnesium in the Human Body: Natural, Metabolizable, and Bone-Regenerative

Magnesium is an essential element for human physiology. Adults contain approximately 21–28 grams of magnesium, with:

- 50% stored in bone

- 35–40% in soft tissue

- ~1% in blood serum

Magnesium ions (Mg²⁺) play important roles in:

- Protein and nucleic acid synthesis

- Cell membrane stability

- Enzyme activation

- Bone formation and mineralization

In orthopedic applications, Mg²⁺ released during degradation can help stimulate osteoblast activity and promote bone healing.

Magnesium implants degrade gradually when in contact with body fluid, forming:

- Magnesium hydroxide (Mg(OH)₂)

- Hydrogen gas

Most degradation products are metabolized via the kidneys or liver, while a small portion is absorbed by surrounding tissues.

3. Applications of Magnesium-Based Materials in Orthopedic and Cardiovascular Devices

(1) Biodegradable Bone Screws and Fixation Devices

Magnesium alloy bone screws have shown promising clinical performance. Benefits include:

- No secondary surgery required for implant removal

- Reduced infection and complication risk

- Better alignment with DRG-based healthcare cost structures

- Suitable for low-load and non-complex fixation procedures

They are especially useful for small-bone fixation and extremity fractures.

(2) Biodegradable Bone Repair Composites

A representative example is the Bogelet® magnesium-containing biodegradable bone repair material developed by Shenzhen Zhongke Jingcheng Medical Technology Co., Ltd.

Core features:

- Composite made from PLGA, β-TCP, and metallic Mg

- Fabricated using low-temperature 3D printing

- Fully degrades in 6–9 months

- Releases Mg²⁺ to accelerate bone formation

- Suitable for extremity bone defect filling and reconstruction

(3) Biodegradable Vascular Stents

Magnesium-based absorbable stents have become an important direction for cardiovascular innovation.

Magmaris® (Second Generation, 2016)

- Biodegradation: ~95% in 12 months

- Provides temporary support during vascular healing

Freesolve® (Third Generation, 2024)

- Alloy: Mg–Al (6.25%)

- Mechanical support for ~3 months

- ~99.3% absorption within 12 months

- Considerably faster than PLLA stents (2–4 years)

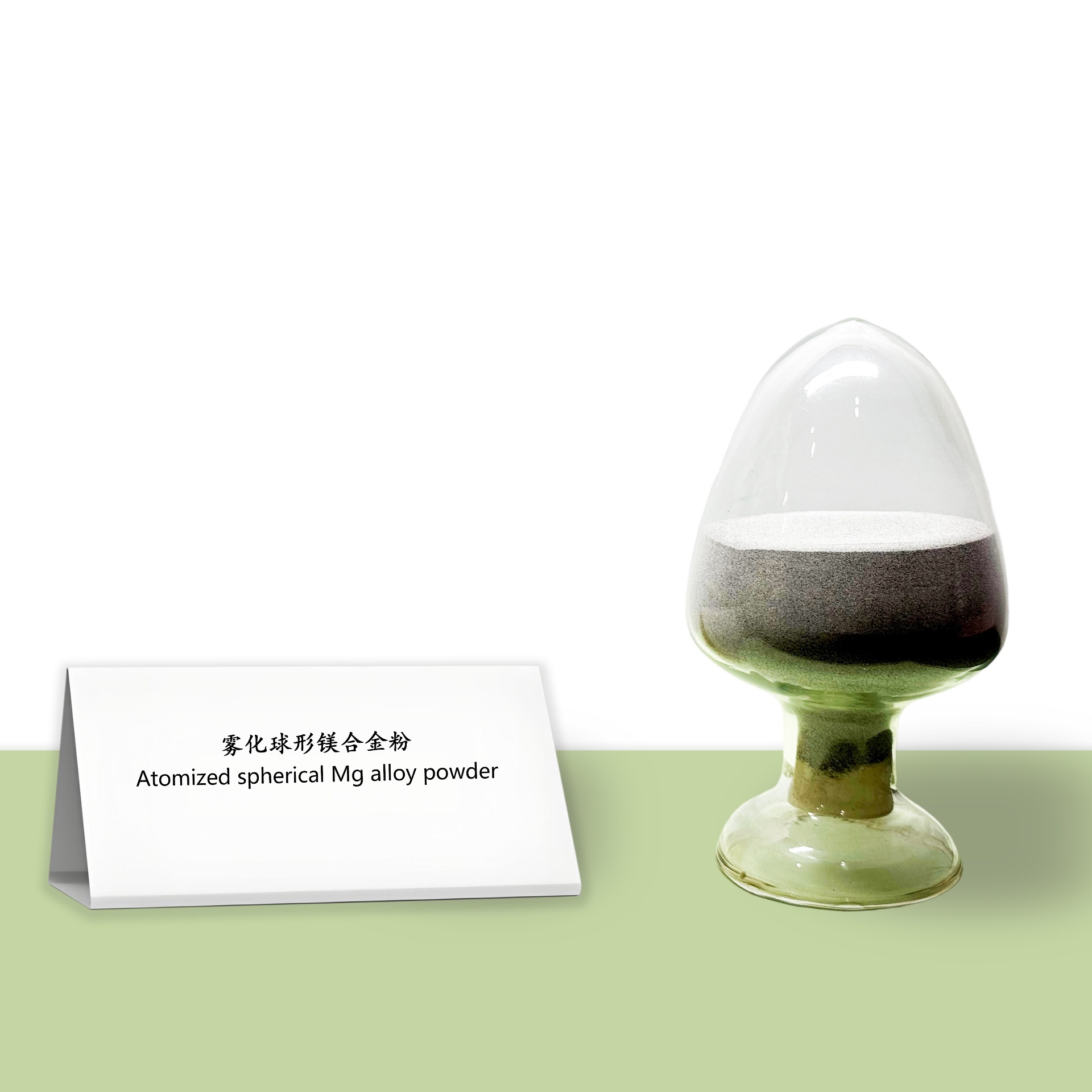

4. Material Supply Support: High-Purity Atomized Spherical Magnesium Powder

As a specialized manufacturer of atomized spherical magnesium powder,

Tangshan Weihao Magnesium Powder Co., Ltd. (www.tswhmf.com)

has been serving global markets since 2000.

Our Powder Advantages

- High purity for improved corrosion control

- Uniform particle size and high sphericity for SLM/LPBF/EBM printing

- Low oxygen content for better degradation stability

- Advanced multi-stage atomization technology

- Supports customized magnesium alloy powder development

As a primary drafter of several national and industry standards, we continue to collaborate with medical device developers, research institutes, and AM innovators.

📩 Contact us: info@tswhmf.com

🌐 Learn more: www.tswhmf.com

Related information