2025-10-09

How Atomized Spherical Magnesium Alloy Powder Enhances SLS 3D Printing Performance?

🔹 Issues of Concern of Customers

How can manufacturers improve the density, mechanical strength, and efficiency of SLS 3D printing while minimizing powder waste? This is a common challenge faced by engineers and researchers working with advanced metal additive manufacturing.

🔹 Pain Points of Industry

Many commonly used powders in SLS 3D printing, such as aluminum or standard alloys, suffer from issues like:

- Poor powder flowability leading to uneven powder spreading.

- Hollow particles that increase porosity and reduce part strength.

- High oxygen content, which negatively impacts mechanical properties.

- Excessive material waste, raising production costs.

These issues create bottlenecks in scaling additive manufacturing for aerospace, automotive, and defense industries.

🔹 Solution: Advantages of atomized spherical magnesium alloy powder

Tangshan Weihao’s atomized spherical magnesium alloy powder offers a breakthrough solution:

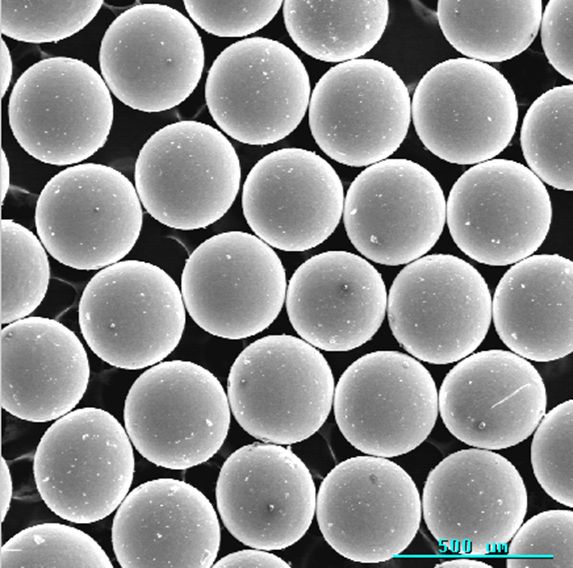

- ✅ High Sphericity → Ensures smooth powder spreading in the SLS process.

- ✅ Low Oxygen Content → Reduces oxidation and ensures superior material stability.

- ✅ No Hollow Powder → Guarantees high density and mechanical integrity in final parts.

- ✅ Excellent Flowability → Improves powder bed uniformity, reducing print defects.

- ✅ Lightweight yet Strong → Perfect for lightweight structural components.

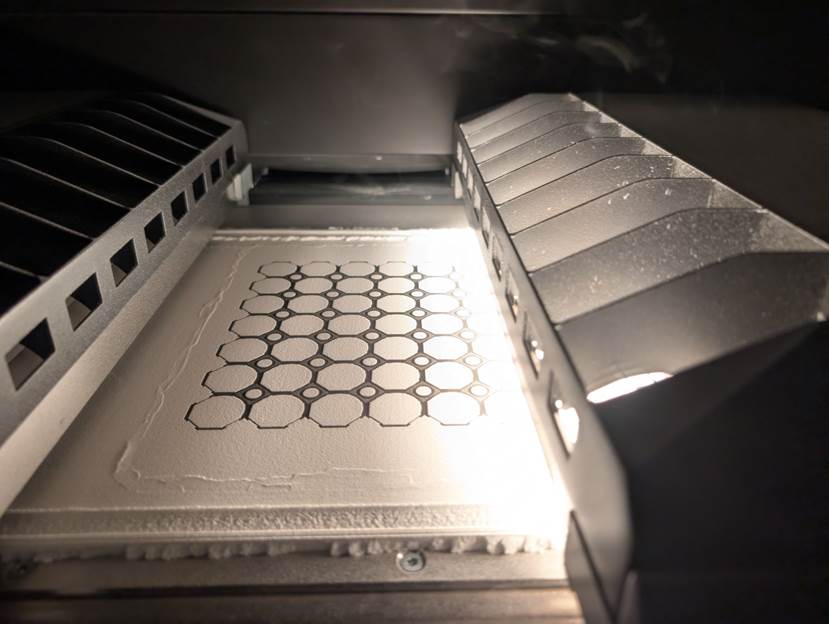

- Spherical magnesium alloy powder for SLS 3D printing

Learn more at 👉 www.tswhmf.com

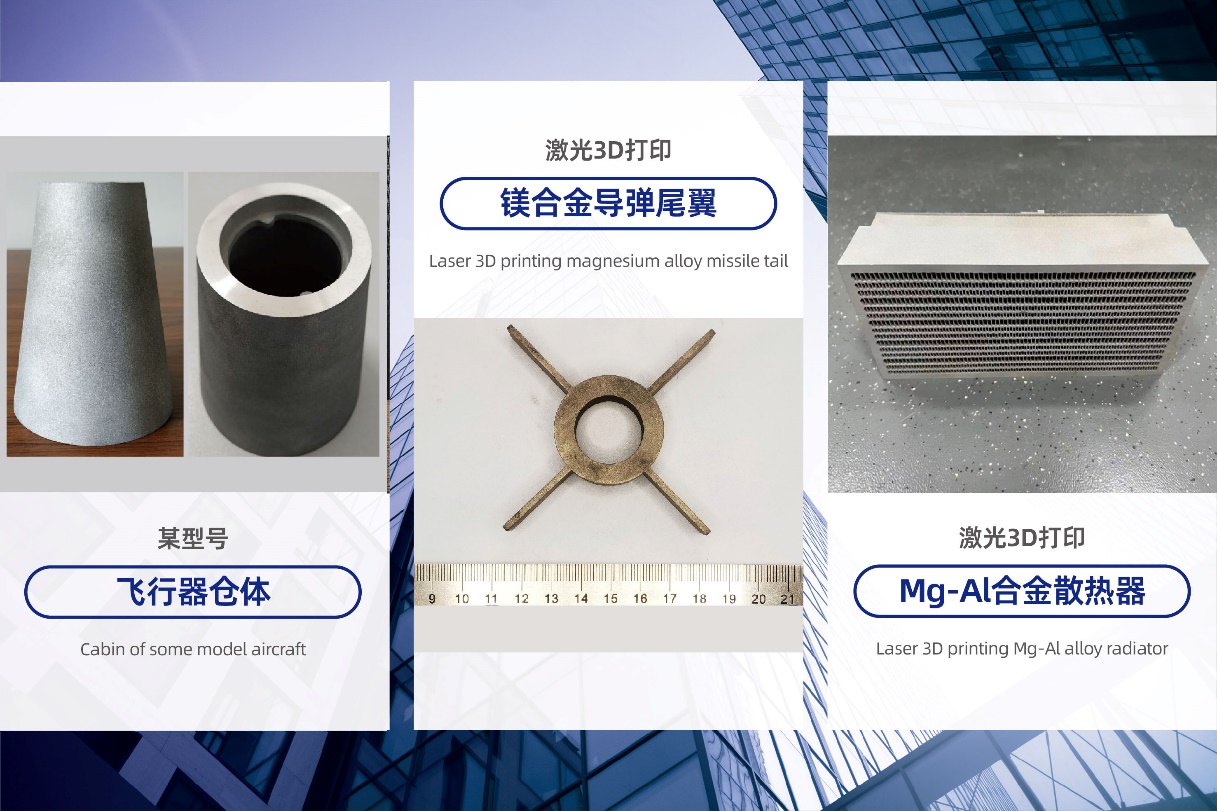

🔹 Application scenarios

- Aerospace: Lightweight brackets and structural parts with high strength-to-weight ratio.

- Automotive: Lightweight body and engine components that reduce fuel consumption.

- Defense: High-performance structural parts requiring stable mechanical strength.

- Medical: Biocompatible lightweight implants and devices.

- Lightweight aerospace parts printed with magnesium alloy powder

🔹 Company Value and Supply Chain Assurance

Tangshan Weihao Magnesium Powder Co., Ltd., established in 2000, is a global leader in high-purity atomized spherical magnesium and magnesium alloy powders. With advanced multi-stage atomization technology and a global distribution network covering 37 countries, we guarantee consistent quality and reliable supply chain support for your projects.

👉 Explore more about our SLS 3D printing powders: www.tswhmf.com

FAQ

Q1: Why is spherical magnesium powder better for SLS 3D printing?

A1: Its high sphericity and flowability ensure uniform powder spreading, improving density and reducing defects.

Q2: How does low oxygen content improve mechanical properties?

A2: Low oxygen prevents oxidation, enhancing stability, strength, and reliability in printed parts.

Q3: Can magnesium alloy powder replace aluminum in additive manufacturing?

A3: Yes, magnesium alloys offer comparable strength with lower density, making them ideal for lightweighting applications in aerospace and automotive.

Related information