2025-10-20

Magnesium Alloy Powder in Robotics Manufacturing: Next-Generation High-Performance Materials

1. Magnesium Alloys: The Core of Lightweight Robotics

Magnesium alloy powder is becoming an essential metal for robotics manufacturing, thanks to its lightweight, high strength, and superior thermal conductivity.

In industrial and humanoid robots, magnesium alloys are widely used in joint housings, transmission systems, skeleton structures, and sensor mounts.

By applying atomized spherical magnesium powder, these parts achieve 30–40% weight reduction without compromising strength, significantly improving energy efficiency and motion response.

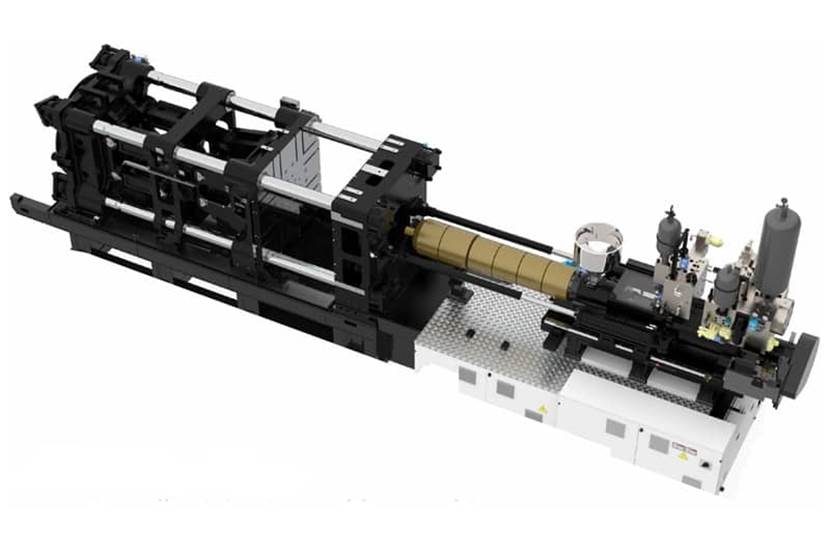

2. Semi-Solid Injection Molding: A Breakthrough in Structural Lightweighting

Semi-solid injection molding is one of the key applications of magnesium alloy powder. This process controls the slurry forming temperature at around 580°C, achieving:

⚙️ Wall thickness below 0.6 mm for high-precision components

💡 Porosity lower than 0.1%, resulting in improved density

⚡ 30% lower energy consumption, supporting green manufacturing

Using Tangshan Weihao’s high-purity atomized magnesium powder, robotic joint housings and gearbox casings gain higher mechanical stability and heat dissipation efficiency.

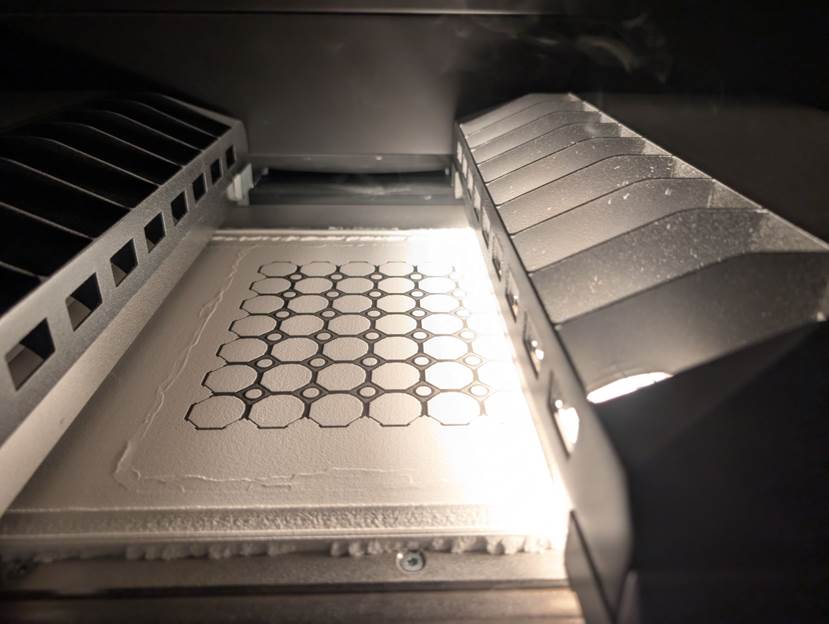

3. 3D Printing: Integrating Complexity and Performance

In metal additive manufacturing, magnesium alloy powder is opening new design possibilities. Through Laser Powder Bed Fusion (LPBF), alloys such as AZ91D and WE43 enable:

🔩 Integrated manufacturing of complex topology structures, reducing weight by 20%

🔬 Low oxygen content and high sphericity, ensuring stable printing

✈️ Ideal for aerospace, robotics, and drone applications

With proprietary atomization technology, Tangshan Weihao achieves uniform particle size distribution, low oxygen level, high tap density, and batch consistency, providing an ideal powder for precision 3D printing.

4. Industry Trends: From Substitution to Performance Evolution

With the mass production of humanoid robots and the trend toward lightweight collaborative robots, magnesium alloys are shifting from being an alternative to aluminum to becoming a multifunctional structural material.

Future directions include:

Rare-earth strengthened Mg alloys – enhancing high-temperature strength and fatigue resistance

Mg-based composites – improving thermal conductivity and electromagnetic shielding

Surface engineering – micro-arc oxidation and electroless nickel plating for better corrosion resistance

Tangshan Weihao continues to advance magnesium alloy powder technology in both 3D printing and semi-solid forming, providing lighter, stronger, and smarter material solutions for the robotics industry.

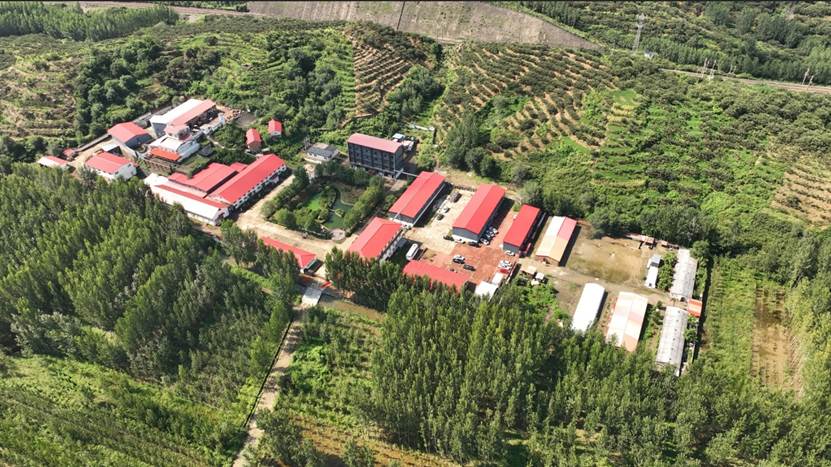

About Us

Founded in 2000, Tangshan Weihao Magnesium Powder Co., Ltd. specializes in the R&D and production of atomized spherical magnesium and magnesium alloy powders. Our materials are widely applied across aerospace, automotive, medical, and consumer electronics industries, helping drive lightweighting, energy efficiency, and precision manufacturing.

With innovation-driven technology and globally distributed partnerships, we are committed to advancing the application of magnesium-based materials in the new era of low-altitude economy and advanced manufacturing.

Partner With Us

If your organization is pursuing innovation in lightweight materials and additive manufacturing, we welcome collaboration through:

Customized Powder Services – Tailored magnesium and magnesium alloy powders matching your design and process requirements.

Joint R&D Projects – Co-developing next-generation lightweight solutions for UAVs and beyond.

Contact Us

🌐 Website: www.tswhmf.com

📧 Email: info@tswhmf.com

📞 Phone: +86-315-2510616

❓ FAQs – Common Questions About Magnesium Alloy in Robotics

Q1: Why is magnesium alloy powder suitable for robotic components? Because of its low density, high strength, and excellent thermal conductivity, which improve efficiency and performance.

Q2: How does semi-solid molding improve component quality? It reduces porosity, increases dimensional accuracy, and improves density compared to traditional casting.

Q3: What types of magnesium alloy powders are used in 3D printing? AZ91D and WE43 alloys are the most widely used for additive manufacturing.

Q4: How is powder purity ensured at Tangshan Weihao? By using multi-stage atomization technology, achieving oxygen content below 0.12%.

Q5: What are the emerging trends in magnesium alloy development? Rare-earth strengthening, magnesium composites, and sustainable green manufacturing.

Related information