2025-08-12

Metal 3D Printed Orthopedic Implants Defy Market Trends with Rapid Growth Atomized Magnesium Alloy Powder Demonstrates Promising Development Advantages

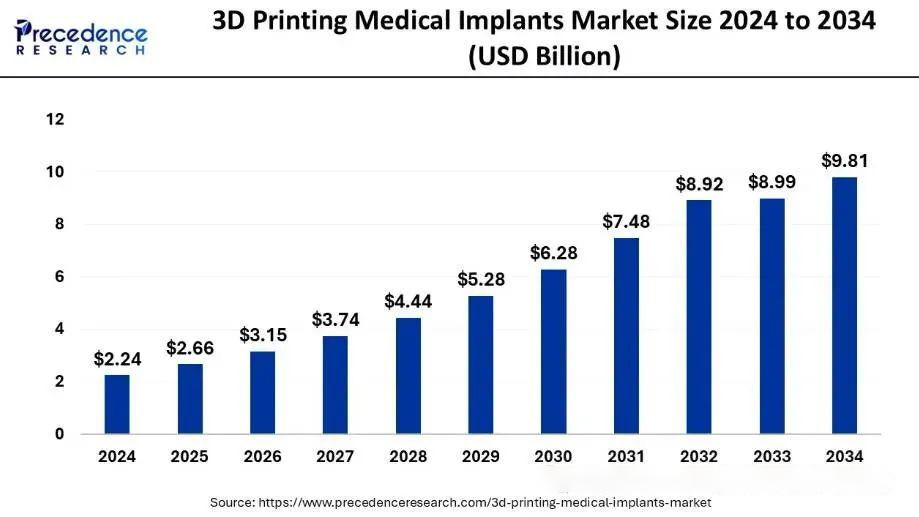

Reference source: https://www.precedenceresearch.com/3d-printing-medical-implants-market

- Surging demand for personalized medicine: Aging populations and increased prevalence of chronic orthopedic conditions are fueling the need for customized implants.

- Policy and insurance support: Initiatives like the U.S. CMS's additional reimbursement for 3D-printed implants are accelerating commercialization.

- Breakthroughs in advanced technologies: Integration of AI with 3D printing and optimization of biomaterials (e.g., titanium alloys, biodegradable composites) enhance implant performance.

Challenges and Future Trends

Despite promising prospects, the industry still faces challenges such as biocompatibility verification, long-term stability validation, and high costs. Addressing these issues requires collaborative efforts across the entire supply chain, including material suppliers, equipment manufacturers, and production facilities, to drive sustained high-speed growth.

Tangshan Wei Hao Magnesium Powder Co., Ltd., a specialized manufacturer of atomized spherical magnesium and magnesium alloy powders, possesses advanced production technology and a rigorous quality control system.

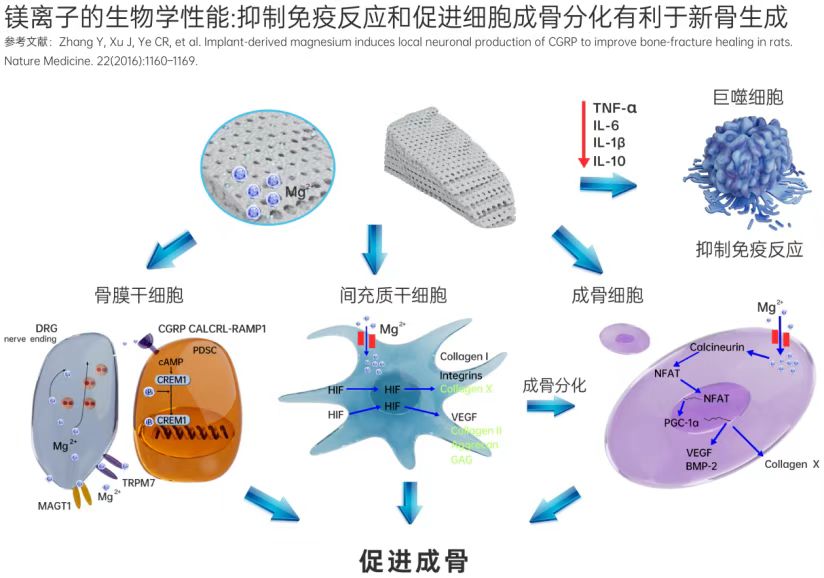

Advantages of Orthopedic Implants Incorporating Atomized Spherical Magnesium Powder:

- Degradation synchronized with bone healing: The degradation rate aligns with the fracture recovery process.

- Biodegradability: Complete absorption within approximately 2–3 years eliminates the need for secondary surgery.

- Exceptional mechanical properties: Combines high strength with low elastic modulus for reliable fixation.

- Superior biocompatibility: Ensures safe and efficient postoperative recovery with no rejection or adverse reactions.

Reference source: https://www.nature.com/articles/nm.4162

If your organization is engaged in innovating metal powder 3D-printed orthopedic implants, we welcome you to collaborate with us for:

- Customized powder solutions: Atomized spherical magnesium and magnesium alloy powders tailored to your product design requirements.

- Joint R&D initiatives: Cooperative exploration of innovative applications for magnesium alloys in 3D-printed orthopedic implants.

About Us:

Tangshan Wei Hao Magnesium Powder Co., Ltd. specializes in the R&D and production of atomized spherical magnesium and magnesium alloy powders, delivering high-performance materials for powder metallurgy applications in aerospace, automotive, biomedical, consumer electronics, and other industries. Driven by technological innovation, we continuously enhance product quality to advance manufacturing efficiency and precision machining.

Contact Us:

Phone: +86-0315-2510615

Email: info@tswhmf.com

Website: www.tswhmf.com

Related information