2025-09-19

Rising Low-Altitude Economy: Magnesium Alloy Powder Empowering Drone Additive Manufacturing

According to the Civil Aviation Administration of China’s Low-Altitude Economy Development White Paper (2024), China’s low-altitude economy is projected to exceed 3 trillion RMB by 2035. As the core carrier of this economy, unmanned aerial vehicles (UAVs) face stringent requirements for lightweight structures and extended endurance.

Technical Challenges

Traditional UAV structures are often built from aluminum alloys and carbon fiber composites. While these materials offer weight reduction, they are prone to fatigue damage under complex mechanical loads. Magnesium alloys, with their high specific strength and superior damping performance, have emerged as ideal candidates to enhance flight stability and endurance. However, the widespread adoption of magnesium alloys in additive manufacturing (AM) has long been restricted by issues such as oxidation and porosity defects.

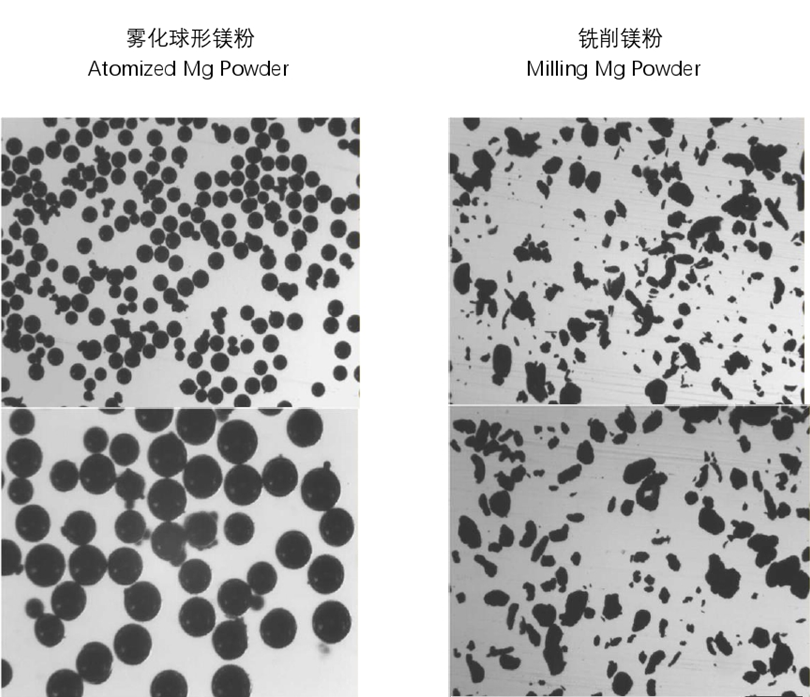

Our Solution: Tangshan Weihao Atomized Spherical Magnesium Alloy Powder

To overcome these barriers, Tangshan Weihao Magnesium Powder Co., Ltd. has developed advanced atomized spherical magnesium alloy powders, designed specifically for additive manufacturing of UAV components:

1.Low Porosity – Leveraging a unique centrifugal atomization process, our powders significantly reduce hollow particles and satellite spheres. This minimizes porosity in printed parts, thereby reducing lack-of-fusion defects.

2.Controlled Oxygen Content – Our optimized production process maintains powders at a low oxygen level, reducing gas porosity during printing and contributing to enhanced mechanical properties.

3.High Sphericity – Powders exhibit a high degree of sphericity, ensuring excellent flowability, uniform powder spreading, and improved wetting during melting.

4.High Tap Density – The powders feature superior packing density, enabling denser powder layers and a stable melt pool, resulting in high-density printed parts with reliable strength.

About Us

Founded in 2000, Tangshan Weihao Magnesium Powder Co., Ltd. specializes in the R&D and production of atomized spherical magnesium and magnesium alloy powders. Our materials are widely applied across aerospace, automotive, medical, and consumer electronics industries, helping drive lightweighting, energy efficiency, and precision manufacturing.

With innovation-driven technology and globally distributed partnerships, we are committed to advancing the application of magnesium-based materials in the new era of low-altitude economy and advanced manufacturing.

Partner With Us

If your organization is pursuing innovation in lightweight materials and additive manufacturing, we welcome collaboration through:

Customized Powder Services – Tailored magnesium and magnesium alloy powders matching your design and process requirements.

Joint R&D Projects – Co-developing next-generation lightweight solutions for UAVs and beyond.

📩 Contact Us

🌐 Website: www.tswhmf.com

📧 Email: info@tswhmf.com

📞 Phone: +86-315-2510616

Related information