2025-09-05

The global aerospace manufacturing industry is facing dual challenges of lightweighting and high performance.

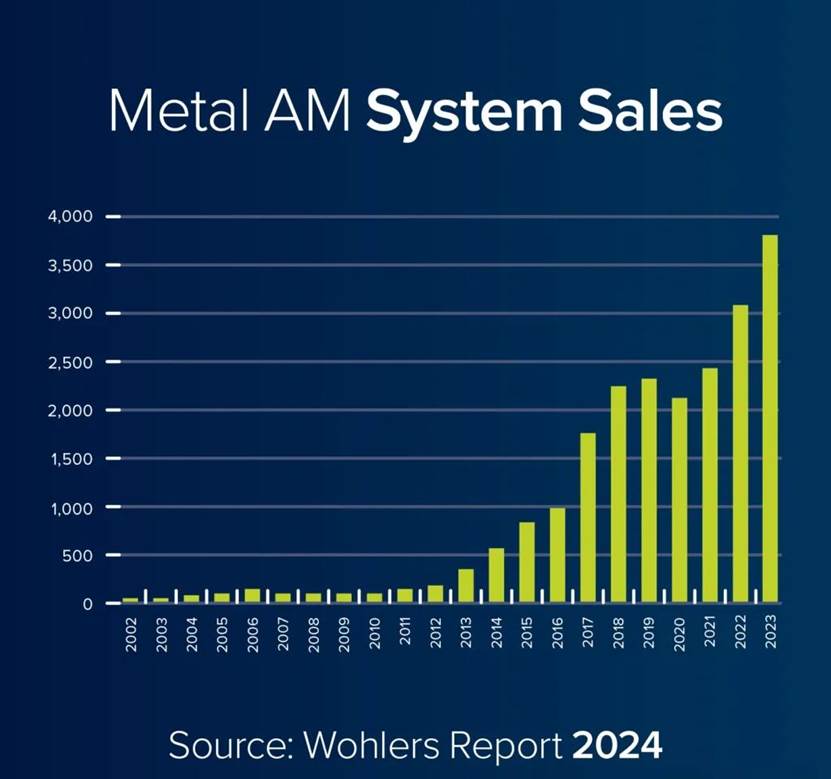

According to Wohlers Report 2024, aerospace has become one of the fastest-growing sectors in the global additive manufacturing market, accounting for over 16%. It is estimated that reducing the launch weight of a spacecraft by 1 kg can save approximately $20,000 to $30,000 in launch costs. Achieving lightweighting while ensuring strength and safety remains a core challenge in material development.

Technical Challenges

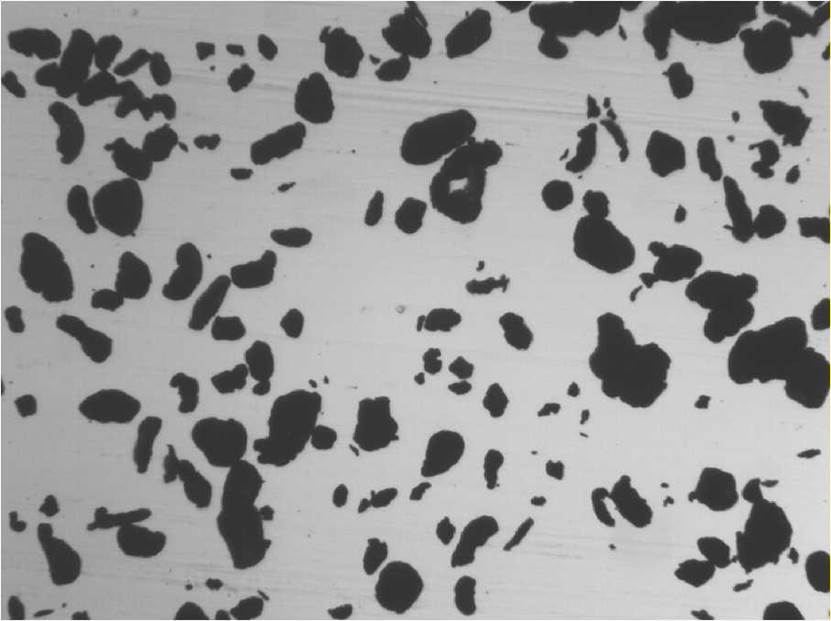

Magnesium alloys, with a density of approximately 1.82 g/cm³—about 35% lighter than aluminum—offer inherent advantages for lightweight applications. However, in additive manufacturing, magnesium powder is prone to oxidation and combustion, and traditional irregular powder morphology often leads to issues such as porosity, cracks, and insufficient strength in formed parts.

Solution

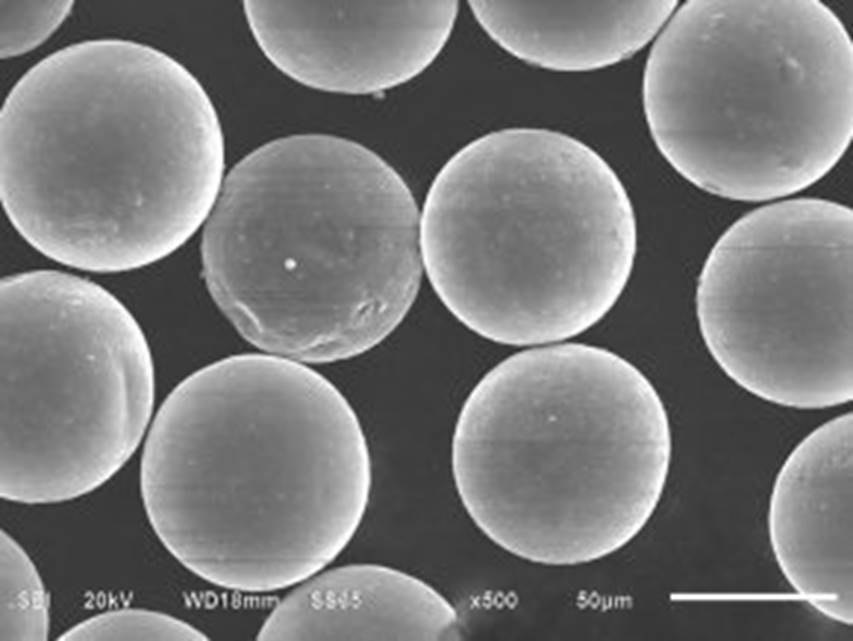

Tangshan Weihao Magnesium Powder Co., Ltd. has developed a proprietary centrifugal atomization process to produce spherical magnesium alloy powder with the following characteristics:

No hollow powder → Significantly reduces porosity, eliminates the risk of "lack of fusion" associated with traditional atomization processes, reduces powder waste, and lowers production costs.

Low oxygen content → Effectively minimizes pore defects and enhances the mechanical properties of components.

High sphericity rate → Uniform gaps between spherical particles improve flowability and powder spreading efficiency. Enhanced wettability during melting reduces printing defects and improves surface quality.

High tap density → Tighter powder packing reduces interlayer porosity. During laser melting, a continuous molten pool is easily formed, achieving a component density of over 99% and mechanical properties close to forged levels.

About Us

Tangshan Weihao Magnesium Powder Co., Ltd. specializes in the R&D and production of atomized spherical magnesium and magnesium alloy powders. We are committed to providing high-performance materials for lightweight applications in industries such as aerospace, automotive, biomedical, and consumer electronics. Driven by technological innovation, we continuously improve product quality to advance energy efficiency and precision manufacturing.

If your organization is engaged in lightweight technology innovation, we welcome you to contact us for:

Customized powder services—Tailored atomized spherical magnesium and magnesium alloy powders to meet your product design needs.

Collaborative R&D—Jointly exploring innovative applications of magnesium alloys in lightweight scenarios.

Contact Information

Tangshan Weihao Magnesium Powder Co., Ltd.

Website: www.tswhmf.com

Email: info@tswhmf.com

Tel: +86-315-2510616

Related information

Tangshan Weihao Magnesium Powder Co., Ltd. | Powered by www.300.cn | SEO | Business License | Privacy Policy | City

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.