2025-08-18

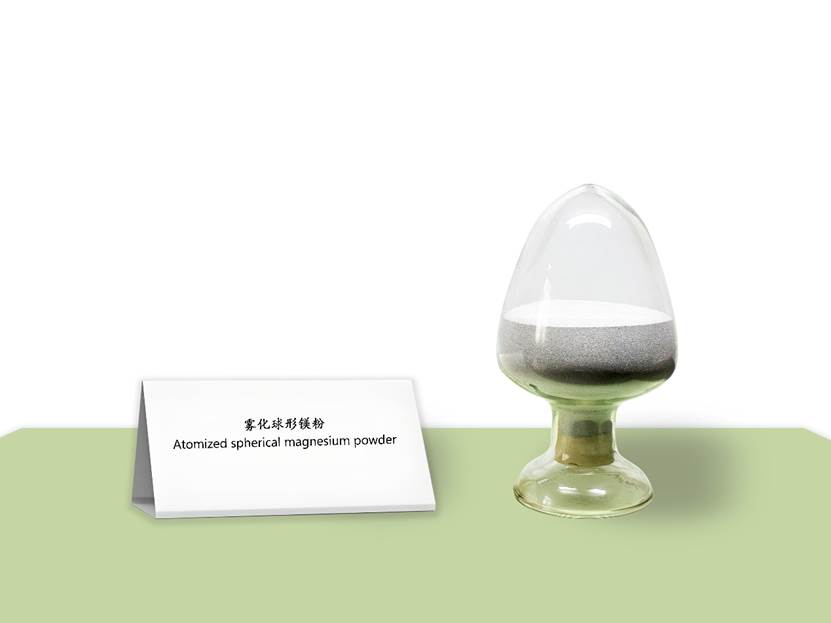

Atomized Spherical Magnesium Powder: A New Choice for High-End Flux-Cored Wires, Enhancing Welding Quality and Performance

Tangshan Weihao Magnesium Powder Co., Ltd. specializes in the R&D and production of atomized spherical magnesium powder and magnesium alloy powders. With innovative technology and high-performance products, the company has become a leading material solutions provider in the welding materials industry.

Technical Requirements for High-End Flux-Cored Wires

As industry demands for welding material performance continue to rise, traditional flux-cored wires increasingly reveal limitations in strength, corrosion resistance, and low-temperature toughness. In critical sectors such as offshore engineering, long-distance oil pipelines, and aerospace, the mechanical properties and reliability of weld seams are paramount. Therefore, the adoption of high-performance magnesium powder as an additive in flux-cored wires has become a key factor in enhancing welding material performance.

Advantages of Atomized Spherical Magnesium Powder

1. High Purity & Low Chlorine Content

Weihao’s magnesium powder, produced via atomization technology, boasts an active magnesium content exceeding 99%, effectively minimizing porosity and inclusions during welding, thereby improving weld seam stability and mechanical properties.

2. Exceptional Flowability & Uniformity

The spherical particles ensure superior flowability and uniform distribution during mixing, enhancing molten pool stability and reducing friction and equipment wear during production.

3. Low Hygroscopicity & Superior Storage Stability

The little specific surface area of atomized spherical magnesium powder results in low moisture absorption, significantly reducing the impact of humidity on welding quality, extending storage life, and ensuring arc stability during welding.

4. Enhanced Weld Seam Performance

Highly reactive atomized magnesium powder promotes deoxidation and denitrification reactions, markedly improving weld seam strength and toughness, particularly in low-temperature environments where impact toughness is significantly enhanced.

5. Increased Welding Efficiency & Cost Savings

Compared to traditional milled magnesium powder, the high flowability of atomized powder streamlines mixing, eliminates additional blending steps, reduces equipment wear and labor costs, and directly boosts production efficiency.

Market Applications of High-End Flux-Cored Wires

High-end flux-cored wires incorporating atomized spherical magnesium powder have been widely adopted in critical domestic and international projects, particularly in offshore engineering, bridge construction, long-distance pipelines, shipbuilding, and thick-plate welding. These wires successfully address inconsistencies in welding material mechanical properties while reducing costs by replacing imported alternatives.

Choose Weihao Magnesium Powder for Industry-Leading Welding Solutions

Whether in offshore engineering, shipbuilding, or aerospace, Weihao Magnesium Powder has become an indispensable partner, thanks to its cutting-edge technology and consistent product quality. Moving forward, Tangshan Weihao Magnesium Powder will continue to invest in R&D, further enhancing product performance, driving industry innovation, and delivering more efficient, reliable welding materials.

Contact us today to revolutionize high-end flux-cored wires

Phone: +86-0315-2510615

Email: info@tswhmf.com

Website: www.tswhmf.com

Related information